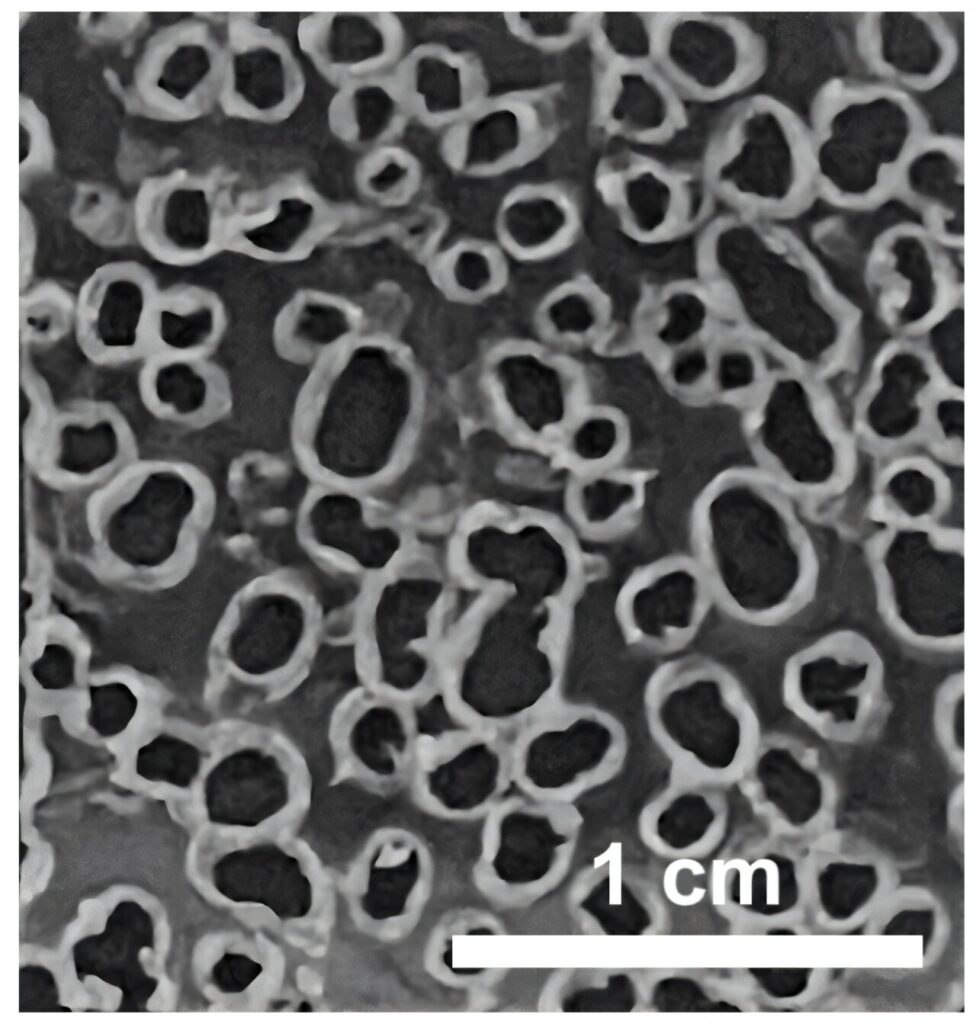

Photo of PET separator. Credit: Energy and Fuels (2025). DOI: 10.1021/acs.energyfuels.5c03370

Many single-use water bottles made from polyethylene terephthalate (PET) end up in landfills, but there is growing interest in upcycling them instead. Energy and fuels researchers report on a new heat-based manufacturing method to convert PET into supercapacitor electrodes and separator films for upcycled energy storage devices. In the demonstration, an all-plastic supercapacitor made from discarded water bottles outperformed a similar design using traditional glass fiber separators.

“PET is used to manufacture more than 500 billion single-use beverage bottles each year, which generates large amounts of plastic waste and poses a major environmental problem,” said lead researcher Yun Han Fu. “PET-derived supercapacitors have great potential for a wide variety of applications in transportation and automotive systems, electronics and consumer electronics, as well as industrial and professional sectors.”

Converting waste plastics such as PET into carbon-based materials, especially conductive materials, is an attractive way to produce more cost-effective and sustainable energy storage devices, such as supercapacitors. These devices use highly conductive carbon electrodes to quickly and repeatedly store and release large amounts of energy. So Hu and his colleagues wanted to upcycle old water bottles into components for a type of supercapacitor called an electric double layer capacitor (EDLC). The device features two porous carbon-based electrodes separated by a thin perforated film immersed in a liquid electrolyte.

Hu’s team has developed two processes to turn used plastic bottles into components for upcycled equipment.

To make the electrodes, the researchers cut plastic bottles into small couscous-sized pieces. They added calcium hydroxide and heated the mixture in a vacuum to nearly 1300 degrees Fahrenheit (700 degrees Celsius). This process converts the plastic into a porous, conductive carbon powder. The researchers combined carbon powder, carbon black, and a polymer binder and dried it to form a thin layer. For the separator, the researchers flattened a small piece of plastic about the size of a postage stamp and used a hot needle to punch holes in it. The hole pattern optimized the passage of current through the electrolyte.

To assemble the PET-based supercapacitor, the researchers immersed two porous carbon electrodes in liquid potassium hydroxide electrolyte and separated them with a perforated PET film. In the demonstration, an upcycled supercapacitor retained 79% of its capacitance (power storage capacity), while a similar device with a glass fiber separator retained 78%.

Hu et al. say the study introduces a potential strategy to convert PET waste into supercapacitor components, “opening new opportunities for circular energy storage technology.” Additionally, they say that upcycled EDLCs cost less to produce than devices made from glass fibers and are themselves fully recyclable.

“With further optimization, PET-derived supercapacitors could realistically move from laboratory prototypes to market-ready devices within the next five to 10 years, especially as demand for sustainable and recyclable energy storage technologies increases,” Hu said.

Further information: Shaoqin Chen et al. “All-plastic supercapacitors from poly(ethylene terephthalate) waste, energy, and fuel” (2025). DOI: 10.1021/acs.energyfuels.5c03370

Provided by the American Chemical Society

Citation: High-performance supercapacitors made from upcycled water bottles (October 9, 2025), Retrieved October 10, 2025 from https://techxplore.com/news/2025-10-high-supercapacitor-upcycled-bottles.html

This document is subject to copyright. No part may be reproduced without written permission, except in fair dealing for personal study or research purposes. Content is provided for informational purposes only.