In this study, the researchers developed a direct plasma-based process to produce carbon and cobalt-tin hydroxide composites. Under appropriate synthesis conditions, the resulting materials exhibit excellent properties as metal-air batteries, paving the way to more sustainable and efficient energy storage for transportation. Credit: Professor Takahiro Ishizaki / Shibaura Institute of Technology pubs.rsc.org/en/content/articlelanding/2025/se/d5se00370a

The search for advanced clean energy solutions is critical as the overuse of fossil fuels has a severe impact on air quality and climate globally. Metal-air batteries offer a game-changing alternative and have the potential to replace combustion engines in a variety of applications.

By electrochemically converting oxygen from the air into electricity, these batteries achieve a theoretical energy density up to 12 times higher than lithium-ion batteries, delivering unprecedented efficiency with zero operational emissions.

Challenges facing the adoption of metal-air batteries

Despite their theoretical advantages, metal-air batteries have not yet been widely put into practical use due to several significant obstacles. Current high-performance catalysts primarily rely on expensive precious metals such as platinum and ruthenium, making mass production and large-scale deployment economically impossible.

Furthermore, most of the existing catalytic materials are monofunctional and can efficiently drive only one of the two essential electrochemical processes, oxygen reduction reaction (ORR) or oxygen evolution reaction (OER), but not both.

Compounding these problems is the complex multistep synthesis process required for these catalysts, which increases manufacturing costs and severely limits scalability.

Innovative research that addresses the limits of catalysts

Against this background, a research team led by Professor Takahiro Ishizaki of Shibaura Institute of Technology’s Faculty of Engineering and Assistant Professor Sang-woo Choi of Nagoya University has been working hard to find appropriate solutions to these problems.

A new study published in Sustainable Energy & Fuels reports an innovative single-step method to create highly effective bifunctional catalysts using abundant, low-cost materials.

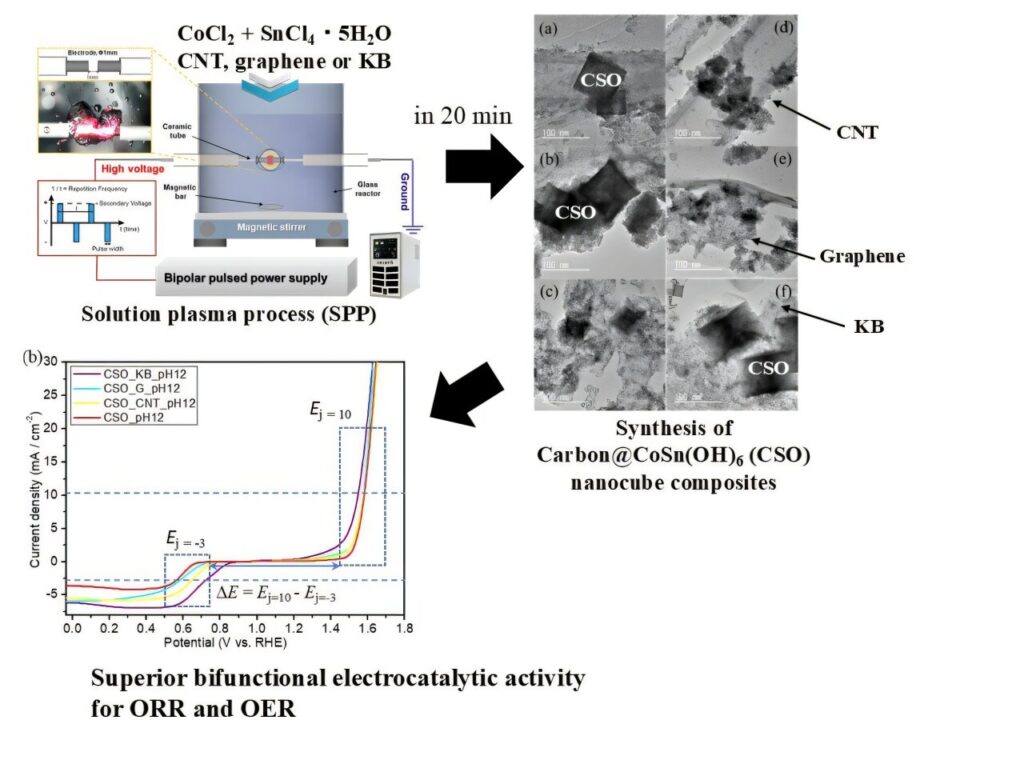

Researchers have successfully fabricated cobalt tin hydroxide (CoSn(OH)6) composites anchored on various carbon supports using a recently pioneered solution plasma process (SPP) for synthesis. This is a decisive difference from conventional catalyst synthesis. Unlike traditional multistep methods that require surfactants and extensive post-processing, SPP allows rapid single-step synthesis at room temperature under ambient atmospheric conditions.

This plasma-based approach not only confers unique surface properties that greatly enhance catalytic activity, but also significantly reduces fabrication complexity and manufacturing costs.

The research team systematically fabricated catalysts with different compositions and carbon structures and rigorously tested the catalysts’ bifunctional performance in both oxygen reduction (ORR) and oxygen evolution (OER) reactions, two crucial processes that determine overall cell efficiency.

The highest performing catalyst combining CoSn(OH)6 and Ketjen black carbon achieved remarkable results. It outperformed industry standard ruthenium oxide catalysts with respect to oxygen evolution, requiring lower voltages to achieve the same current density. In oxygen reduction, it demonstrated performance comparable to much more expensive platinum-based catalysts, while relying solely on abundant feedstock.

Furthermore, as Professor Ishizaki says, this new catalyst has proven to be very durable. “Our advanced CoSn(OH)6-Ketjenblack composite showed exceptional long-term stability, maintaining excellent oxygen evolution performance for more than 12 hours without degradation, which is an important factor for practical battery applications.”

In particular, the ability of catalysts to efficiently catalyze both necessary reactions represents a major advance in this field. The researchers measured a potential difference of only 0.835 V between the two reactions, allowing for highly efficient energy conversion. This dual functionality eliminates the need for a separate catalyst, further reducing system complexity and cost.

Detailed analysis confirmed that the excellent catalytic performance was attributed to the strong synergistic interaction between (CoSn(OH)6) nanoparticles and carbon support.

The researchers found that the SPP synthesis process is important. The SPP synthesis process uniformly distributes active nanoparticles across the carbon surface, maximizing the exposure of catalytic sites while ensuring excellent electrical conductivity.

Additionally, this method allows precise control of particle size and critical surface properties, allowing for systematic optimization of catalytic activity.

“This breakthrough has great potential for the customized production of high-performance, durable, and low-cost bifunctional electrocatalysts for critical energy conversion systems,” Professor Ishizaki emphasizes. “This provides a truly sustainable alternative to the precious metal-based catalysts used commercially.”

Energy storage and industrial impact

The impact of this initiative is far-reaching and is expected to revolutionize the entire energy sector. Metal-air batteries equipped with these newly developed catalysts have the potential to fundamentally transform energy storage in electric vehicles, providing significantly longer range and faster charging capabilities while reducing overall costs.

Additionally, this technology has immense potential for grid-scale energy storage, which is important for efficiently integrating intermittent renewable power sources such as solar and wind into power networks. The proposed one-step synthesis method offers significant industrial advantages as well.

By eliminating complex multi-step processing and reliance on expensive raw materials, manufacturers will be able to produce these high-performance catalysts at a fraction of their current costs. Additionally, these materials can be synthesized under ambient conditions, significantly reducing energy consumption and environmental impact compared to traditional high-temperature, high-pressure methods currently used to manufacture batteries and catalysts.

Overall, this research represents an important and transformative step toward achieving economically viable clean energy storage on a global scale and is poised to significantly accelerate the essential transition away from fossil fuels in the transportation and energy sectors.

Further information: Sangwoo Chae et al., Single-step solution plasma synthesis of bifunctional CoSn(OH)6-carbon composite electrocatalysts for oxygen evolution and oxygen reduction reactions, Sustainable Energy and Fuels (2025). DOI: 10.1039/d5se00370a

Provided by Shibaura Institute of Technology

Citation: Plasma-based method creates efficient, low-cost catalysts for metal-air batteries (November 17, 2025) Retrieved November 18, 2025 from https://techxplore.com/news/2025-11-plasma-based-method-efficient-catalysts.html

This document is subject to copyright. No part may be reproduced without written permission, except in fair dealing for personal study or research purposes. Content is provided for informational purposes only.