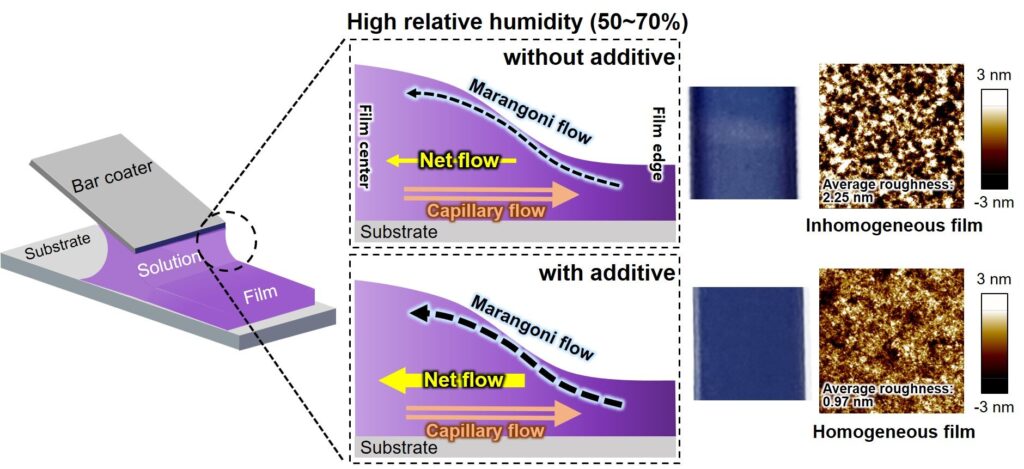

The additives introduced into the solution to prepare the photoactive layer promote marangoni flow, thereby offsetting capillary flow caused by changes in the substrate surface energy due to relative humidity, and suppressing net flow fluctuations induced by humidity. Credit: Korea Institute of Science and Technology (KIST)

As global demand for renewable energy grows, solar cells continue to attract attention as an important clean energy source. Among these, solution-treated solar cells can be manufactured simply by coating and drying an ink-like material on a large surface, offering advantages such as low cost and scalability.

However, this process has traditionally been sensitive during environmental humidity, especially during humid summers, and requires maintaining low humidity conditions, resulting in unstable performance and high manufacturing costs.

A research team at the Korea Institute of Science and Technology (KIST), led by the son of Dr. Hae Jung of Advanced Photovoltaics Research Center, has developed a new dielectric additive-based coating technology that ensures that high-performance organic photovoltaic power (OPV) can be produced regardless of seasonal humidity changes.

The team’s findings were published in Joule magazine.

Researchers introduced Carvone (CV), a low-cost dielectric additive, into the photoactive layer solution. CV forms a non-covalent complex with the organic acceptor material (L8-BO), promoting crystallization and stabilizes the internal flow during the blade coating process. This is an important step in the manufacture of solar cells. This change creates a uniform photoactive film even under ambient relative humidity in the range of 10% to 70%.

By utilizing D18 and PM6 as donor materials and N3 and L8-BO together with the addition of N3 and L8-BO as the accedor materials, we fabricated an organic photovoltaic (OPV) module with an active area of 20.33 cm2, showing an output conversion efficiency (PCE) of 16.27%. Credit: Korea Institute of Science and Technology (KIST)

When applied to solar cell manufacturing, the CV-based process results in a power conversion efficiency (PCE) of 16.27% for large area modules (20.33 cm2) compared to 15.1% for traditional methods.

In particular, seasonal efficiency variations remained within ±2%. This is lower than the typical deviation observed with commercial grade solar panels.

Beyond performance improvements, new technologies eliminate the need for costly drying chamber facilities. Instead, manufacturers can simply mix the additive solution into existing coating solutions and use current equipment without changing them. This dramatically reduces production costs and makes the solution particularly attractive for mass production.

The global market for next-generation, highly efficient solar cells is projected to reach around US$1.5 trillion ($2,000 trillion) due to intense technological competition from countries such as China and the United States.

The photoactive layer coating process may be less susceptible to relative humidity, and the resulting OPV may be less susceptible to seasonal changes. Credit: Korea Institute of Science and Technology (KIST)

The CV-based approach developed by KIST provides Korea with a strategic edge by simultaneously providing high efficiency and economic scalability.

Dr. Son of Kist said, “The technology addresses the long-standing reproducibility issues caused by humidity fluctuations, providing a scalable pathway to low-cost, stable, and high-performance solar energy production. We are currently expanding this approach to tandem solar modules and looking for collaboration with industrial and global research partners.”

Details: Sungmin Park et al, Dielectric Additives allow for the preparation of high performance, most organic photovoltaic, humidity-independent forms for Joule (2025). doi:10.1016/j.joule.2025.101927

Journal Information: Jour

Provided by the National Council on Science and Technology

Quote: The new solar cell coating maintains high efficiency despite being obtained on July 18, 2025 from https://techxplore.com/news/2025-07-solar-cell-cell-celating-high-efficiency.html despite summer humidity (July 18, 2025).

This document is subject to copyright. Apart from fair transactions for private research or research purposes, there is no part that is reproduced without written permission. Content is provided with information only.