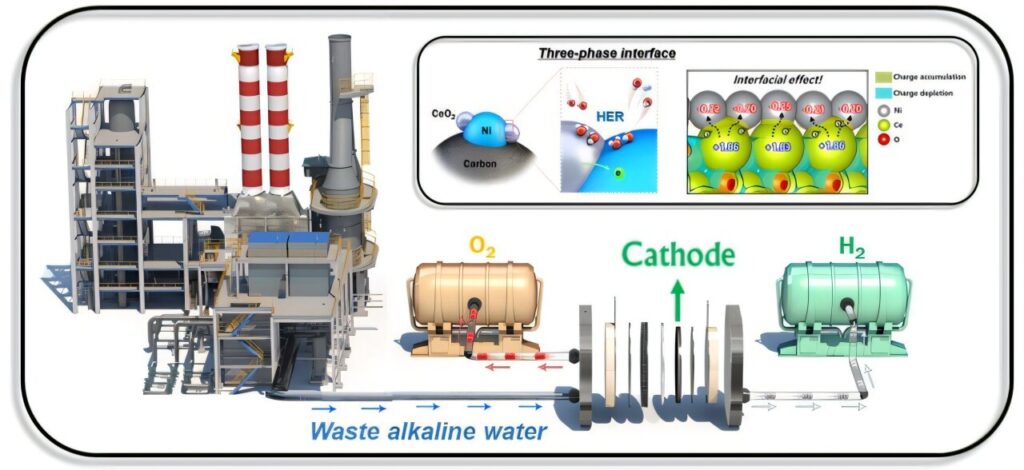

Anion exchange membrane water dissolution for clean hydrogen production by directly utilizing industrially generated waste alkaline water. Credit: Korea Institute of Materials Science (Kims)

Dr. Song Mook Choi of the Department of Energy & Environmental Materials Research at the Korea Institute of Materials Science (KIMS) and his research team have successfully developed a highly durable, non-priority metal-based hydrogen evolution catalyst for use in direct electrolysis systems using waste alkaline water and anion exchange membrane (AEM). This breakthrough allows for the production of clean hydrogen by directly utilizing alkaline wastewater produced from industrial processes.

In particular, the developed catalyst was applied to commercial scale 64cm² single-cell electrolytic systems, demonstrating high hydrogen production efficiency with performance degradation of less than 5% even after continuous operation of more than 2,000 hours.

Waste alkaline water is produced in large quantities from semiconductor manufacturing and metal etching/cleaning processes. However, due to the high cost of treatment and potential environmental hazards, its reuse remains economically inefficient.

Anion-exchange membrane electrolysis (AEMWE) is considered an appropriate method for direct use of waste alkaline water without the need for individual purification. Nevertheless, impurities and ions contained in wastewater have long hindered electrochemical reactions during electrolysis, significantly reducing hydrogen production efficiency.

The researchers found that the interface between nickel and cerium oxide exhibits a weak binding energy with impurity ions present in waste alkaline water. This finding was theoretically verified through collaboration with Professor Min Ho Seo of Pukyong National University using density sensory theory (DFT) calculations.

Additionally, in collaboration with Professor Jang Yong Lee of Konkuk University, researchers have developed an extremely durable anion exchange membrane that can maintain performance in impurity-rich environments.

Through this development process, the researchers created heterostructured non-preferred metal catalysts based on nickel and cerium oxide. This catalyst can be applied directly to water electrolysis systems using waste alkaline water without the need for a complex purification process. As a result, the team not only reduced hydrogen production costs, but also established technical breakthroughs.

Synthesis and surface characterization of NCC. a) Synthesis and structural properties of NCC. b) HR-TEM and enlarged images of the NCC of the interface between NC and CEO2. Credit: Advanced Science (2025). doi:10.1002/advs.202502484

Traditional freshwater-based electrolysis systems require approximately 18 tons of raw water to produce one ton of hydrogen, from which approximately 9 tons of Ultrapier water must be extracted. The cost of purifying this amount of water is estimated to be around US$2,340. In contrast, the “Direct Waste Alkaline Water Electrolysis Technology” developed by the research team uses large amounts of waste alkaline water without purification, which dramatically reduces the cost of hydrogen production.

The researchers have synthesized heterostructured non-preferred metal catalysts based on nickel and cerium oxide. This facilitates large-scale production by dissolving and precipitating multiple substances simultaneously.

The final catalyst was obtained through a two-stage heat treatment process. This approach allows the formation of numerous oxygen vacancies, maximizes electron-metal-support interaction (EMSI), improving both catalytic performance and durability.

Oxygen vacancies promote smoother electron flow, accelerate hydrogen evolution reactions (HER), and the strong interaction of metals with surrounding materials improves operational stability and efficiency of the catalyst.

When commercialized, the technology is expected to accelerate the self-sufficiency of key component materials in the future mobility and electricity industry, and will contribute to the creation of a new market for clean hydrogen. Based on this finding, the research team is also working to develop next-generation AEMWE technology that uses seawater as its source directly.

“Through this research, we demonstrate that industrial waste alkaline water can be effectively recycled for hydrogen production, minimizing the risk of leakage accidents during wastewater transport while significantly reducing production costs.”

“Non-new water-based electrolysis technology is expected to attract attention in the field of clean hydrogen production in the future.”

Details: Kim et al’s NAM disrupts the bottleneck due to the interfacial effect of Ni/CEO2 on long-term hydrogen production using waste alkaline water in a practical anion exchange membrane water electrolyzer, Advanced Science (2025). doi:10.1002/advs.202502484

Provided by the National Council on Science and Technology

Quote: Direct electrolytic system turns waste alkaline water into clean hydrogen (July 21, 2025) Retrieved from https://techxplore.com/news/2025-07-07-Electrolysy-hydrogen.html on July 21, 2025

This document is subject to copyright. Apart from fair transactions for private research or research purposes, there is no part that is reproduced without written permission. Content is provided with information only.