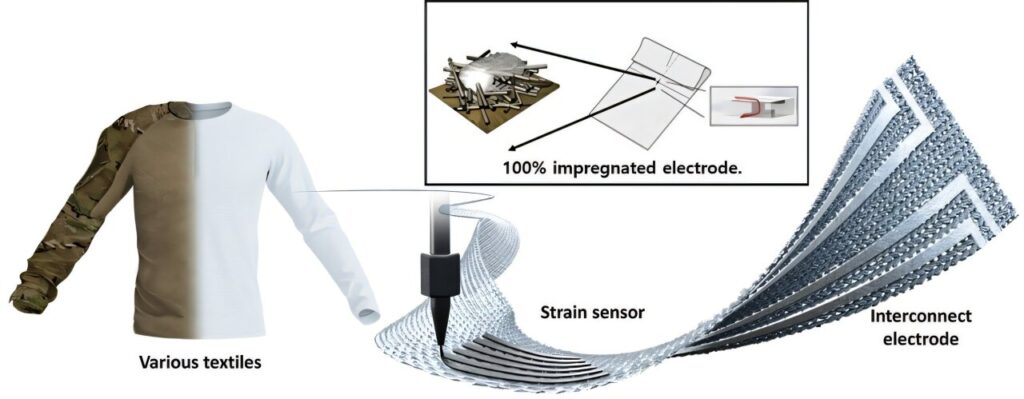

Schematic diagram of electronic textiles manufactured using direct inking (DIW) printing techniques for various textiles, including combat uniforms. Credit: NPJ Flexible Electronics (2025). doi:10.1038/s41528-025-00414-7

Traditional military training often relies on standardized methods that limit the provision of optimized training tailored to individual combatants’ characteristics or specific combat situations. To address this, the research team has developed an e-textile platform to protect individual combatants and core technologies that can reflect the unique characteristics of various combat scenarios. The technology has proven robust enough for use on the battlefield and is economical enough for wide distribution to large numbers of military forces.

On June 25th, Professor Steve Park, a research team from Kaist’s Faculty of Materials Science and Engineering, announced the development of a flexible, wearable e-Textile platform using innovative technology that “draws” electronic circuits directly on fabrics. This study is published in Journal NPJ Flexible Electronics.

Developed by the research team, the wearable E-textile platform combines 3D printing technology with new material engineering designs to print flexible, durable sensors and electrodes directly onto the fiber board. This allows for accurate movement and human body data collection from individual combatants, and can be used to propose customized training models.

Existing e-textile manufacturing methods have often been complicated or limited in their ability to provide personalized customization. To overcome these challenges, the researchers adopted an additive manufacturing technology called Direct Ink Writing (DIW) 3D printing.

This technology involves dispensing and printing special inks that act as sensors and electrodes directly and printing them on a fiber substrate in the desired pattern. This allows for flexible implementation of various designs without the complex process of mask manufacturing. It is expected to be an effective technology that can easily be supplied to hundreds of thousands of military personnel.

Measurement of human movement and breathing patterns using electronic textiles. Credit: NPJ Flexible Electronics (2025). doi:10.1038/s41528-025-00414-7

The core of this technology lies in the development of high-performance functional inks based on advanced material engineering designs. The researchers combine styrene-butadiene-styrene (SBS) polymers to provide flexibility and feature multi-walled carbon nanotubes (MWCNTs) for electrical conductivity.

They have developed a tensile/bending sensor ink that can grow to 102% even after 10,000 repeated tests and maintain stable performance. This means that accurate data can be consistently retrieved even during the intense movements of combatants.

Additionally, new material technology has been applied to implement “interconnection electrodes” that electrically connect the upper and lower layers of the fabric. The team developed an electrode ink that combines silver (AG) flakes with a hard polystyrene (PS) polymer, effectively connecting both sides or multiple layers of the fabric with precise control over impregnation levels (how much ink penetrates the fabric). This protects the technology for producing multi-layer wearable electronic systems that integrate sensors and electrodes.

The researchers then demonstrated the platform’s performance through real human movement monitoring experiments. They printed e-Textiles on the main joint areas of the clothing (shoulders, elbows, knees) during various exercises such as running, jump jacks, and push-ups to measure measured movement and posture changes.

Experimental results of machine learning six objects using smart gloves and then recognizing unknown objects. Credit: NPJ Flexible Electronics (2025). doi:10.1038/s41528-025-00414-7

Experimental results showing that multilayer electronic textile gloves connected to interconnection electrodes can measure tensile/bending and pressure signals at a single point. Credit: NPJ Flexible Electronics (2025). doi:10.1038/s41528-025-00414-7

Additionally, they demonstrated the potential for applications such as monitoring breathing patterns using smart masks, recognizing objects through machine learning, and printing multiple sensors and electrodes on gloves to recognize complex tactile information. These results show that the developed e-textile platform is effective in accurately understanding the dynamics of combatant movement.

This study is an important example of how state-of-the-art new materials technologies can contribute to advancement in the defense sector. Army Major Kyusoon Pak, who participated in this study, considered necessary goals such as military applicability and economic feasibility for practical distribution from the research design stage.

Major Pak said, “Our military forces are currently facing both crisis and opportunity due to the decline in military personnel resources caused by demographic cliffs and advances in science and technology. Respect for life on the battlefield has also emerged as an important issue.

“The purpose of this study is to ensure original techniques that can provide customized training according to military sector/duty and type of combat, thereby increasing combat power and ensuring soldier survivability.”

He said, “I hope this research will be appreciated as a case that achieves both scientific contributions and military application.”

Details: Manufacturing of multifunctional wearable interconnected e-textile platforms using Kyosoon Pak et al, Direct Ink Writing (DIW) 3D Printing, NPJ Flexible Electronics (2025). doi:10.1038/s41528-025-00414-7

Provided by Korea Institute of Advanced Science and Technology (KAIST)

Quote: Flexible E-Textile uses 3D printed sensors to monitor and optimize the combat training routine (2025, June 30) obtained from https://techxplore.com/2025-06 on June 30, 2025.

This document is subject to copyright. Apart from fair transactions for private research or research purposes, there is no part that is reproduced without written permission. Content is provided with information only.