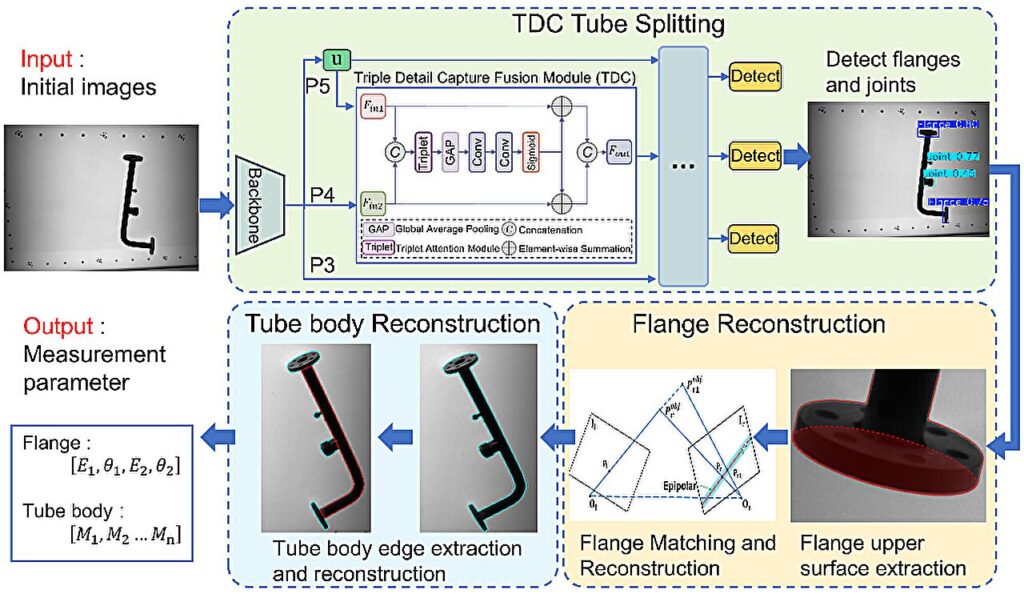

An overall flow chart of an online measurement method for complex pipelines based on area pre-segmentation. Credit: SIA

Complex tubes with flanges, joints and other components featuring numerous diverse geometries and complex structures are an important part of aircraft engines, rockets and other equipment. To ensure smooth operation of this instrument, the tube dimensions must be ensured.

A research team at the Institute of Automotive Automation (SIA) at the Chinese Academy of Sciences has developed a new online measurement method based on multi-camera vision and pre-segmentation of the region. This new approach allows for real-time, high-precision inspection of the spatial dimensions of the flanges and joint tubes.

This study, published in the Journal of Manufacturing Processes, introduces a segmentation model equipped with triple-detail feature capture fusion (TDC). This model effectively integrates multi-scale visual capabilities, allowing the system to identify key structural regions such as flanges and joints for accurate segmentation.

To quantify the flange geometry, the researchers proposed an edge-based measurement algorithm focusing on the top surface of the flange. Accurate parameter extraction was achieved by analyzing changes in curvature and applying 3D reconstruction. For tube body regions, often linear yet fragmented structures, the researchers reconstructed the central axis to determine important spatial measurements.

Experimental results show that the system can complete the full tube measurement in just 7 seconds. The flange parameter accuracy is 0.17 mm and the tube body parameter accuracy is 0.16 mm.

Details: Hao Zhao et al, Multi-camera vision online measurement method of complex tube parameters based on local pre-segmentation, Journal of Manufacturing Processes (2025). doi: 10.1016/j.jmapro.2025.05.083

Provided by the Chinese Academy of Sciences

Quote: The new multi-camera vision system enables rapid and accurate online measurements of complex tubes obtained from July 21, 2025 from https://techxplore.com/news/2025-07.

This document is subject to copyright. Apart from fair transactions for private research or research purposes, there is no part that is reproduced without written permission. Content is provided with information only.