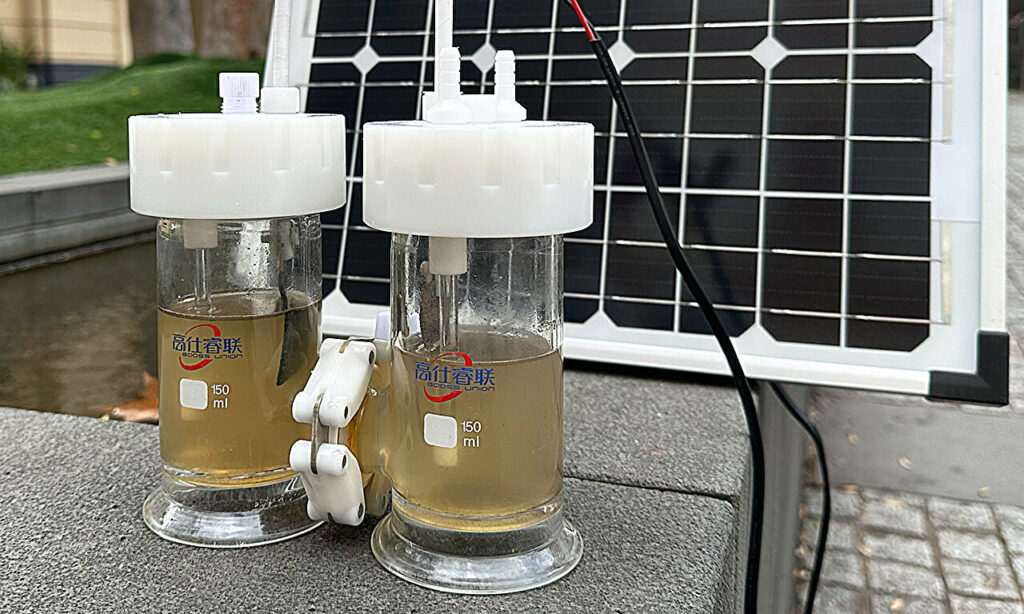

An experimental setup of team hydrogen production using partially treated wastewater and solar power generation. Credit: Shu Shu Zheng from RMIT University

A study led by RMIT University has developed an experimental invention to favor high pollution loads of wastewater to create green hydrogen, which can reduce its dependence on freshwater, a rare resource in many parts of the world.

This study offers an opportunity to increase productivity by increasing this environmental responsibility, as more than 80% of the world’s wastewater has been discharged into untreated environments.

The team’s approach leverages some of the contaminants in the wastewater to speed up hydrogen production and overcome high pollutant loads that normally cannot be used.

The latest work by the team involved with the University of Melbourne, Australia’s Synchrotron and the University of New South Wales is a building from previous breakthroughs, including innovations that use magnets to rapidly remove microplastics from water and technology that uses seawater to enhance hydrogen production.

“Utilization of wastewater as a catalyst modifier for sustainable hydrogen production” is published in the ACS Electrochemistry.

How innovation works

Nasir Mahmood, a principal investigator and associate professor at RMIT’s science school, said the team found ways to capture other metals, nickel, in the water, and how these elements work to enhance green hydrogen production.

“The advantage of innovation over others to produce green hydrogen is that it utilizes the unique materials of the wastewater, rather than requiring cleansed water or additional steps,” Mahmoud said.

Their essential inventions are provided in the form of electrodes, which are key components for splitting water into hydrogen and oxygen. The electrodes are made of absorbent carbon surfaces that attract metals from wastewater, forming a stable and efficient catalyst for electrical conduction, helping to accelerate water splitting.

The materials used in the production of special carbon surfaces are made from agricultural waste. This is a cost-effective aspect of innovation that contributes to a growing circular economy.

“The catalyst speeds up chemical reactions without being consumed in the process,” Mahmoud said.

“Metals interact with other elements in the wastewater to enhance the electrochemical reactions needed to split water into oxygen and hydrogen.”

As part of the experiment, the team used wastewater samples in a container with two electrodes (positive anode and negative cathode)) to drive the inundation process with renewable energy. When electricity flows through water, a chemical reaction occurs.

At the cathode, water molecules acquire electrons and form hydrogen gas. At the anode, water molecules lose electrons and form oxygen.

As a result, water can be separated into basic components, hydrogen and oxygen, and then both can be collected and used.

“The oxygen produced can be reintegrated into wastewater treatment plants to increase efficiency by reducing organic content,” says Mahmood.

The device allowed for 18 consecutive days of water splitting during laboratory experiments, minimizing performance degradation during which time. As part of the experiment, the team used wastewater treated with solid waste, organic matter and nutrient removal.

Industry and government cooperation opportunities

RMIT has developed a platform for catalytic systems that can use previously difficult water resources such as wastewater and seawater, and this latest proof-of-concept invention is a further example of the system under development.

Co-led researcher Professor Nikki Eschtiagi said the latest RMIT innovations could potentially reduce the high costs of wastewater treatment and turn it into something worthwhile.

“Our innovation is working to both reduce pollution and water shortages, which benefits the energy and water sector,” said Eshtiaghi, Rmit’s Faculty of Engineering. “By using wastewater, this process reduces pollution and helps to utilize materials that are considered waste.

“We want to work with businesses around the world who are working on cost and sustainability challenges and as a water authority, energy and waste.

“Collaboration can focus on developing commercial systems for the use of this technology at scale.”

Next Steps

Collaborator Dr. Muhammad Harris said further research is needed to improve the catalytic process, making it even more efficient and commercially suitable.

“This method needs to be ensured to work universally for testing with different types of wastewater,” says Harris, an engineering school.

Details: ACS Electrochemistry (2025) leveraging wastewater as a catalyst modifier for sustainable hydrogen production. doi:10.1021/AcseLectrochem.5C00064

Provided by RMIT University

Quote: Wastewater Pollutants Boost Green Hydrogen Production (July 16, 2025) Retrieved from https://techxplore.com/news/2025-07-wastewater-contaminants-boost-green-hydrogen.html

This document is subject to copyright. Apart from fair transactions for private research or research purposes, there is no part that is reproduced without written permission. Content is provided with information only.