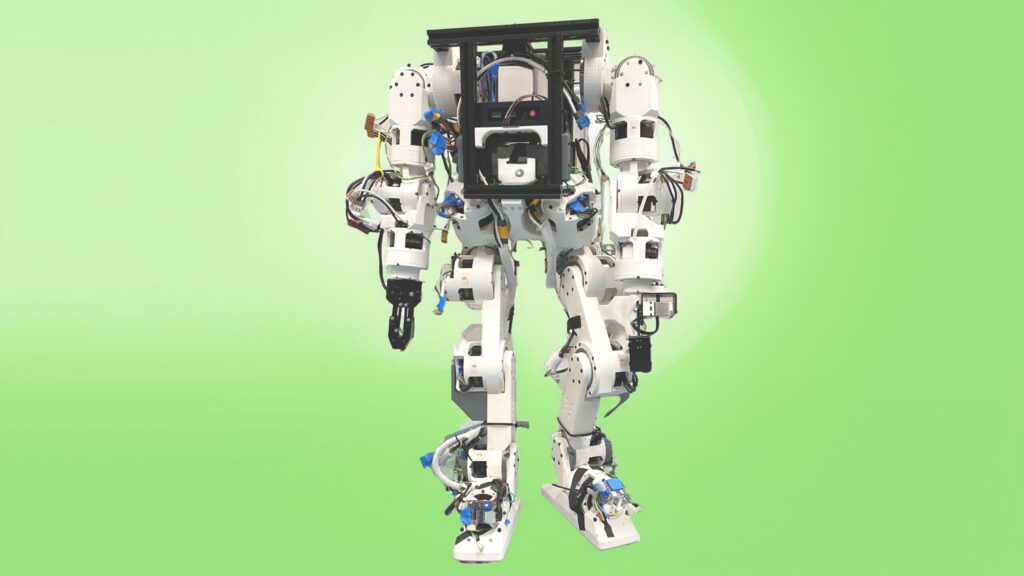

The Berkeley Humanoid Light stands about 1 meter and weighs about 16 kg. Credit: University of California, Berkelly University

As an undergraduate, Yufeng Chi (BS’23 EECS) was fascinated by humanoids and legged robots. Wanting to learn more, he jumps into a class project by watching YouTube videos, but it wasn’t easy to tinker with hands-on experiences.

“I was interested in building my version of the humanoid robot, but at the time, actuators, motors, robot kits etc were not widely available. The developers kept the source code private,” he said. “So I started looking for a way to do it. [make a] DIY robot. ”

Now PhD Chi is a student in the Faculty of Electrical Engineering and Computer Science and is part of a team of Berkeley Engineers who developed the Berkeley Humanoid Lite, a low-cost, open-source robot made from 3D printed parts. They recently published a paper on their work at the 2025 Robotics Science Systems Conference (RSS 2025) held in Los Angeles from June 21-25.

Humanoid robotics has evolved rapidly over the years, and devices are now designed for industrial automation, healthcare, research and personal support applications. Despite growing interest in the field, Chi said most commercial hardware remains relatively expensive.

Over time, the cost has become a simple problem that solves. He said the bigger challenges are dealing with the issues of customization and resources.

Commercial companies may provide fully built robots, but the unique nature of hardware and software designs often makes it difficult to replace parts or change components. This limits the opportunity for beginner robotic players to experiment with customization and further explore the boundaries of humanoid technology.

At the same time, not everyone has access to cutting-edge equipment. “Some research projects assume you have access to flashy CNCs. [computer numerical control] Uses advanced manufacturing machines and customized PCBs [printed circuit boards] “In the case of electronics,” Chi said. “In a fully equipped lab, creating robots from scratch may be feasible, but for many people, including enthusiasts and DIYers, it’s out of reach.”

By developing Berkeley Humanoid Light, researchers aimed to provide launch points for those interested in humanoid technology.

“Our aim is to help people in the field of research and education become familiar with how humanoid systems work by providing templates to start, including how to assemble and develop robotic platforms,” he said. “It’s all about looking at sample systems and building this system one after another from scratch. Then, after gaining experience and confidence, you can build it and take it to a new level.”

The Berkeley Humanoid Lite design core is a modular 3D printed gearbox for actuators and robot bodies. All other components can be sourced from widely available e-commerce platforms or manufactured with standard desktop 3D printers. This will result in a total hardware cost of less than $5,000 (based on US market prices), a mere portion of the cost of purchasing a commercial robot of a similar size. Additionally, you can easily manufacture the replacement of broken or worn parts using a 3D printer.

Once completed, the Berkeley Humanoid Light stands at about 1 meter and weighs about 16 kg.

Chi estimates that this timeline can vary depending on your skill set and experience level, but it will take a novice robotic player about a week to build your own Berkeley Humanoid Light. “The good news is that we’re watching our discord and chatting with other community groups and we see our users actually build it,” he said. “They displayed photos of the assembled robots, which is very exciting.”

Since Chi began working on Berkeley Humanoid Lite four years ago, new startups have begun selling more affordable metal actuators. However, Chi believes that the modularity of the Berkeley Humanoid Lite offers an important advantage over commercial products.

“Use our approach to build one actuator, spin it, then try putting multiples into a simple arm or leg,” he said.

Recognizing that the 3D printed parts essentially lack the strength of materials such as aluminum, researchers adopted a cycloid gear design for the gearbox within the actuator.

“The main advantage is that the gear teeth are very large,” Chi said. “This distributes load over a larger surface area than traditional gear systems, reducing stress and wear.”

Additionally, several aspects of the 3D printed actuator were tested to verify durability. “Our findings showed that 3D printed actuators were at least comparable to other actuators,” Chi said.

He said, “We designed this so that if the actuator fails, another gearbox could be printed and replaced. [but] Even after all these experiments have been realized, it is not yet possible to destroy a single actuator with any of the test robots. ”

Researchers also tested the ability of Berkeley Humanoid Lite to complete simple tasks such as grabbing objects and walking forward.

To enable manual operation, researchers assembled a teleoperation system for the robot. Using joystick controls, they demonstrated the ability of Berkeley Humanoid Light to grab and play items containing Rubik’s Cubes. The researchers also used reinforcement learning to develop a mobile controller that allows bipedal robots to walk.

Chi said that while the robot’s mobility skills are “a little unstable and not very elegant”, he hopes that the Berkeley Humanoid Light community will work together to improve the software code over time and resolve the bug.

Berkeley Humanoid Lite’s hardware design, built-in code, training and deployment framework are completely open source. Researchers wanted users to see how everything works and make it easy to customize the robot.

“I believe in the spirit of open-force communities, the ideas of ecosystems where people share ideas and knowledge,” Chi said. “Our hope is that Berkeley Humanoid Light will help us closer to democratizing the development of humanoid robotics.”

In addition to CHI, co-authors of this study include Koushil Sreenath, an associate professor of mechanical engineering and lead researcher. PhD students in mechanical engineering Qiayuan liao, Junfeng long, Xiaoyu huang, Zhongyu li. Associate Professor Sofia Xiao and Boliboe Nikolic, professor in both the Department of Electrical Engineering and Computer Science.

Details: Demonstration of Berkeley Humanoid Light: Open Source, Accessible, Customizable 3D Printed Humanoid Robot. roboticsconference.org/program/papers/62/

Berkeley Humanoid Light: Open Source, Accessible, Customizable 3D Printed Humanoid Robot

Provided by the University of California – Berkeley

Quote: 3D Printed Humanoid Robots provide an affordable, customizable platform for beginners, obtained from June 26, 2025 from https://news/2025-06-3d-humanoid-customizable-platform.html from June 26, 2025 (June 26, 2025)

This document is subject to copyright. Apart from fair transactions for private research or research purposes, there is no part that is reproduced without written permission. Content is provided with information only.