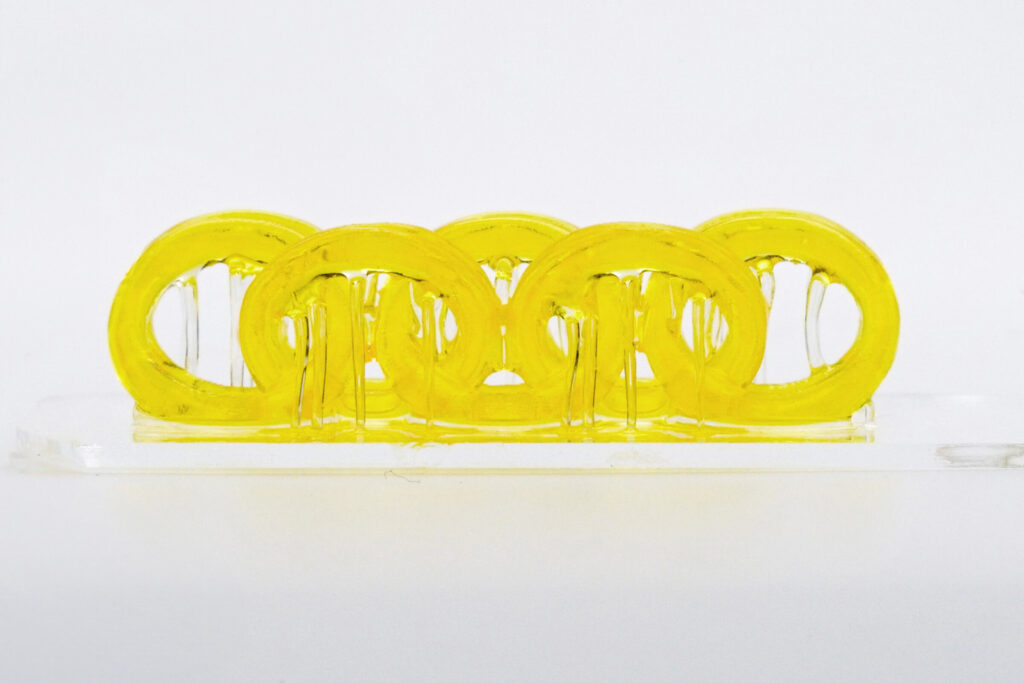

The results of new methods for printing objects using new resins provide similar flexibility, strength and complexity to those found naturally. Credit: University of Texas at Austin.

Researchers at the University of Texas in Austin were inspired by how nature fuses toughness and flexibility, including the rigid structure of bone surrounded by flexible cartilage, with elegant and precise geometric properties.

This advancement could pave the way for next-generation prosthetics, flexible medical devices, and elastic electronics that move naturally like human joints and ligaments. This process is explained in a paper published today at Nature Materials.

“It’s really motivated that me and my research group are essentially looking at the material,” said Zach Page, a UT Austin professor of chemistry and corresponding author. “Nature does this in an organic way, combining hard and soft materials without breaking down on the interface. We wanted to replicate that.”

A related paper published May 29 by Page and other authors from ACS Central Science explains the adjacent work that journal editors praised in their “first reaction” commentary, and the work represents the “future of 3D printing” and “light as a tool for curing resin.”

“This approach could make additive manufacturing more competitive for more capacity production compared to traditional processes such as injection molding. Equally important, it opens up new design possibilities,” says Keldy Mason, the lead author of the latter study and a graduate student at Page’s lab. “This allows engineers, designers and manufacturers to create more freedom.”

One of the biggest challenges in creating objects with very different physical properties is that materials tend to fail at interfaces, or the points they come into contact with. Think about how the rubber sole of a running shoe will separate over time from the soft mesh cloth above it.

The new 3D printing method uses a custom designed liquid resin and a double optical printing system that activates different chemical reactions depending on the color of the light used. By making the violet light shine, the resin heals into elastic rubber-like materials. However, in areas that collide with high energy UV rays, they become stiff and stronger. The result is an object with a clear zone of softness and hardness made from a single print.

“We incorporated the molecules with both reactive groups, so the two solidification reactions were able to “discuss each other” at the interface,” Page said. “This gives us a much stronger connection between the soft and hard parts, allowing us to gradually transition if necessary.”

The team demonstrated the system by printing small but functional knee joints with flexible ligaments and stiff bones that move smoothly together. They also created a prototype stretchable electronic device with gold wires attached to strips where the parts could bend and stretched, but with stiffer sections to prevent the circuit from breaking.

“To be honest, what surprised me the most was how well it worked in the first attempt. That never happens with 3D printing resins,” Page said. “We were also shocked at how different the properties were. The soft parts stretched and bouncing like rubber bands. The hard parts were as strong as the plastic used in consumer products.”

Additionally, this process works faster and at better resolution than previous approaches. Additionally, the printer setup is relatively simple and affordable, making this technology likely to be accessible to researchers, hospitals and educators.

“It can be used for surgical models, wearable sensors, or prototypes of soft robots,” Page said. “There’s so many possibilities here.”

Details: Hybrid Epoxy-Acrylate Resin for Wavelength Selective Multi-Material 3D Printing, Natural Materials (2025). doi:10.1038/s41563-025-02249-z

Keldy S. Mason et al., Multicolor Digital Light Processing 3D Printing, enables disbandable support for self-supporting and non-assembled structures, ACS Central Science (2025). doi:10.1021/accentsci.5C00289

Provided by the University of Texas at Austin

Quote: Dual-Light 3D printing technology enables a seamless blend of flexible rigid materials (2025, June 30) obtained on June 30, 2025 from https://techxplore.com/news/2025-06.

This document is subject to copyright. Apart from fair transactions for private research or research purposes, there is no part that is reproduced without written permission. Content is provided with information only.