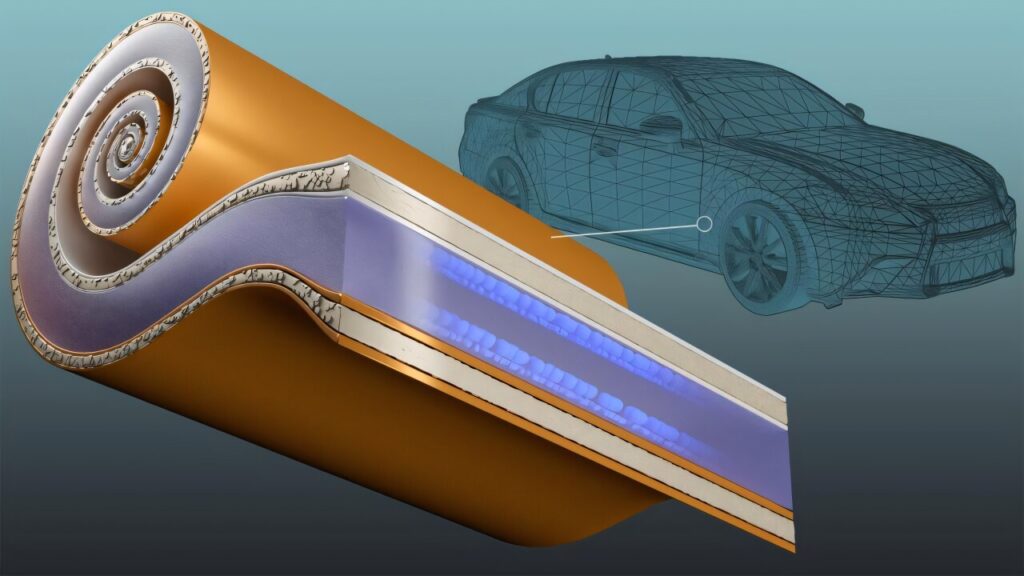

Researchers have developed a new type of lightweight, affordable current collector that transfers power from electric vehicle batteries to the car, allowing for both long driving ranges and extreme fast charging. Credit: Andys Pro Wrestling/Ohn, US Energy Department

The strengthening of the American transportation industry’s competitiveness relies on the development of domestically produced electric vehicle batteries that allow for rapid charging and long distance performance. However, the energy density required to extend the operating distance can be done at the expense of charging rate and battery life.

By integrating the current collectors of a new type, the main battery component, researchers at the Department of Energy’s Oak Ridge National Laboratory have demonstrated how to manufacture batteries with both excellent energy density and permanent ability to handle extreme fast charging. This will restore at least 80% battery energy in 10 minutes. By using fewer metals, especially copper, which is high in demand, the technology also reduces the burden on the US supply chain.

“This saves a lot of near-critical materials because it contains far less copper and aluminum,” says Georgios Polyzos, a researcher at Reed. “At the same time, this significantly increases the energy density that can be achieved with a 10-minute charge.”

The current collector conducts electricity from the active material in the battery to external circuits. Current collectors are generally made of metal foil, with one for each pole of the electrode. Cathode and aluminum copper. Metal adds weight to the battery, increasing the overall weight of the car and the amount of energy needed to move it.

The new current collector created by industry partner Soteria Battery Innovation Group is a polymer sandwiched between very thin copper or aluminum. ORNL researchers have discovered that this new component can reduce current collector costs by 85%, pack 27% energy for long trips, and maintain a significant energy density after 1000 cycles. The new current collector works just like traditional counterparts at about a quarter of your body weight, allowing the EV to move further on the same charge.

ORNL researchers have created coin and pouch cell batteries using industry standard processes at ORNL’s open access battery manufacturing facility to expand the technology for commercialization.

Polyzos said the team has identified parameters for successfully incorporating thin materials into the roll-to-roll production process despite being prone to wrinkles. Other experimental current collectors generally require expensive and complex manufacturing processes that are incompatible with standard roll-to-roll methods.

ORNL’s research, published in Energy & Environmental Materials, highlights the possibility of “revolutionizing the roll-to-roll battery manufacturing process and significantly improving performance indicators for lithium-ion batteries for electric vehicle applications.”

Brian Morin, CEO of South Carolina-based Soteria, said ORNL helped them understand how to achieve rapid battery charging with technology despite increased physical resistance from plastic films.

“We take 80% of the metal and it’s hard to do things quickly,” Morin said. “However, they showed you can still get faster charge and discharge. Testing on Soteria shows that the polymer makes the battery safer. If there is an internal short circuit that produces a short lash of energy, it will take away the metal film. It will pull the metal apart.

Details: Yue Feng et al, Metallized Polymer Current Collector for High Energy Lithium-Ion Battery with Extreme Fast Charging Capacity, Energy and Environmental Materials (2025). doi:10.1002/eem2.12878

Provided by Oak Ridge National Laboratory

Quote: The new component reduces the cost and supply chain constraints (2025, June 26th) of fast-charged EV batteries obtained from June 26th, 2025 from https://news/2025-06-component-chain-constraints-fast-ev.html.

This document is subject to copyright. Apart from fair transactions for private research or research purposes, there is no part that is reproduced without written permission. Content is provided with information only.