Lithium-metal batteries have not hit the market yet, but if they do, they could be a solution to the everyday woes of the dwindling battery meter. They are cousins of the lithium-ion batteries found in legions of everyday electronic devices, but with the potential to hold twice as much power. Unfortunately, the lithium-metal battery’s limited number of recharges has been a major obstacle to their wide adoption.

A new study led by researchers at the California NanoSystems Institute at UCLA, or CNSI, however, might just help ratchet up the pace of progress. In the journal Science Advances, the team documented an imaging technique they invented that—for the first time ever—captures a lithium-metal battery as it charges, at a level of detail smaller than the wavelength of light.

The method, electrified cryogenic electron microscopy, or eCryoEM for short, yielded insights that may help guide the design of better lithium-metal batteries. Cultivating this progress with U.S.-based research could give the U.S. an edge in this successor technology to lithium-ion batteries, an industry currently dominated by Chinese enterprises. The study also holds promise for shedding light on mysteries in disciplines as far afield as neuroscience.

Corresponding author Yuzhang Li, an assistant professor of chemical and biomolecular engineering at the UCLA Samueli School of Engineering and CNSI member, answered a few questions about his team’s advance.

What motivated this research?

China really dominates the entire lithium-ion battery supply chain, with nearly 80% made or processed there. It’s going to be difficult to compete, which is a big issue if we are to move the U.S. economy toward technologies such as electric vehicles and grid-scale energy storage.

Lithium metal could give the United States some potential to leapfrog lithium-ion batteries. Compared to lithium-ion, lithium metal essentially doubles your battery’s energy density. However, the cycling stability of lithium metal is just not there yet.

We get thousands of charging cycles from lithium-ion batteries, but we’re barely reaching 200 with the best-performing lithium-metal batteries in the research literature. One of the reasons is that lithium metal is extremely reactive. A corrosion layer forms between the lithium and the liquid electrolyte in the battery, and it’s a big topic of research.

What makes eCryoEM different from previous techniques in cryogenic electron microscopy?

The cryoEM tools for physical sciences are no different from the ones in biology. For batteries, they’re basically postmortem techniques: We can only capture electrochemical reactions in their initial and final states. There’s a blind spot for what’s happening under reaction conditions.

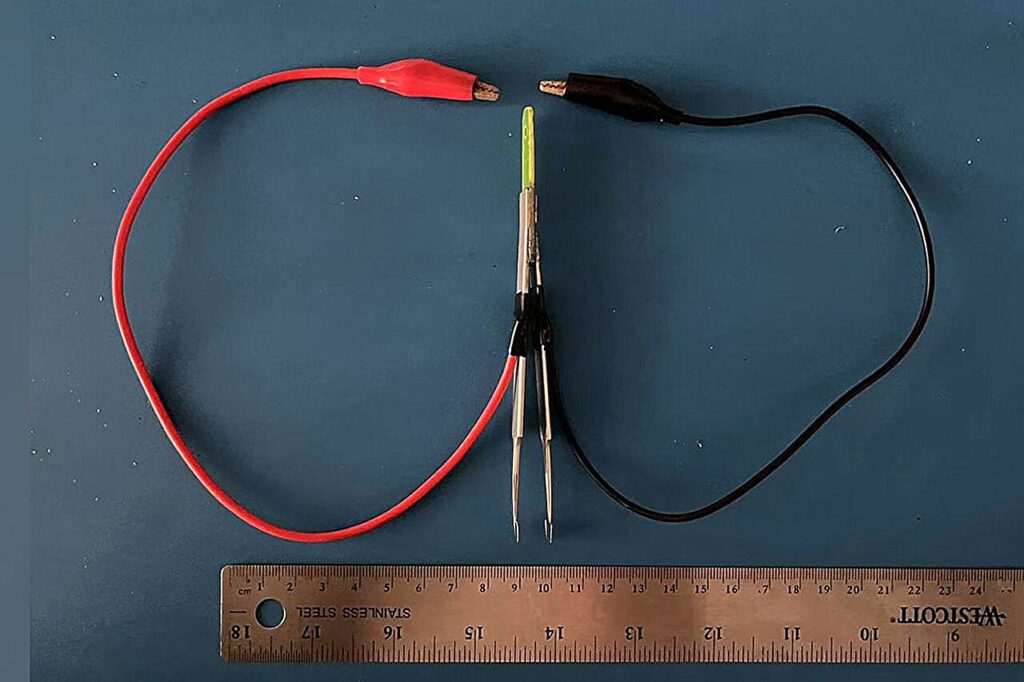

In this technique we’ve been developing over the last four years, we said, “Let’s throw a battery in liquid nitrogen while it’s charging.” In order to do that, we had to engineer a very thin battery, and we had to plunge freeze it directly so that it freezes very fast, on the order of milliseconds. We had to ensure that there were no side reactions during that process.

We froze batteries at various time points. When we bring together many of these measurements in sequence, it becomes a bit like a flipbook animation where we watch that corrosion film grow over time. And if we understand that, it’ll help us engineer better batteries.

What did you find out?

We compared two distinct electrolyte chemistries, high-performing and low-performing. You can recharge one maybe 100 times and the other one only 50 times.

The leading hypothesis has been that the difference in performance has something to do with the corrosion film, which allows lithium ions to come through the layer but stops electrons from passing. This prevents the electrolyte from continuously reacting with the lithium metal. The thinking has been that the diffusion of electrons through the corrosion layer must be slower with the high-performing electrolyte, which means less corrosion.

Using eCryoEM, we plotted the thickness of the corrosion layer over time. At early stages, the growth rate is only limited by how fast the lithium can react. Once the corrosion film gets thick enough, growth is limited by how quickly the electrons diffuse through it.

It turns out that during the diffusion-limited stage, the corrosion film does grow slower with the high-performing electrolyte, but only by about 10%. During the early, reaction-limited stage, there’s a much larger difference, by a factor of three. That was a bit of a surprise.

What are the implications for lithium-metal battery design?

In this field, we’ve been focusing on engineering the properties of the corrosion layer to limit diffusion. But the major difference doesn’t seem to be how fast electrons go through; it’s how reactive the electrolyte is.

The findings suggest we should dedicate some engineering to making the liquid electrolyte as inert as possible. This is not a novel concept, but the study quantifies just how large a difference that could make and highlights this is a potentially promising approach.

It seems that the eCryoEM technique itself has broader implications for areas from engineering to the life sciences.

Electrified cryoEM could be the next generation of cryoEM for materials science. My group is interested in fundamentally understanding the molecular-scale processes in applications spanning supercapacitors and technologies that convert carbon dioxide to fuels. We have private foundation funding through a Packard Fellowship to explore this.

The thing I’m most excited about, though, is contributing to the biology community. A large part of my career has benefited from traditional cryoEM, which is really a technique for structural biology.

How are you giving back to biology?

Like batteries and electronics, the brain’s function is based in electricity. Our idea is simply, “Let’s zap a brain cell at various voltages and freeze it in that dynamic state.” Changes in the shape of a protein that regulates how ions move across the cell membrane can help us understand how it functions. And if we study disease models, we might be able to generate insights into new therapies.

The co-first authors of the study are UCLA doctoral students Chongzhen Wang and Jung Tae Kim. Other co-authors are Xintong Yuan, Jin Koo Kim, Bo Liu, Min-ho Kim and Dingyi Zhao, all of UCLA.

More information:

Chongzhen Wang et al, Trapping and imaging dynamic battery nanointerfaces via electrified cryo-EM, Science Advances (2025). DOI: 10.1126/sciadv.adv3191

California NanoSystems Institute

Citation:

New imaging method reveals how lithium-metal batteries lose capacity over time (2025, June 14)

retrieved 15 June 2025

from https://techxplore.com/news/2025-06-imaging-method-reveals-lithium-metal.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.