Summary

We don’t need sweeping digital promises. We need precise, human-first solutions that bridge the gap between theory and practice.

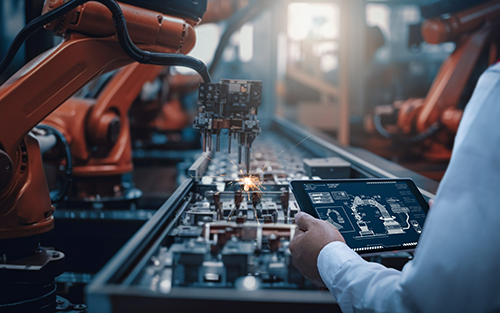

American manufacturing is at a crossroads. Labor shortages, fragile supply chains, fixed-price constraints and a growing tech divide are squeezing the industry at a time when global demand has never been stronger. The urgency to increase throughput, precision and resiliency is especially acute in sectors that impact national security, like aerospace and defense. And yet, despite the promise of advanced automation and AI, the leap from theoretical capability to practical deployment on the factory floor remains steep.

Today’s manufacturers don’t just need more tools. They need smarter, more adaptive systems. AI can’t simply be dropped into production environments. To deliver real value, industrial AI must be deeply integrated, earn credibility in use and empower, not replace, the skilled people who make manufacturing work. If we want to move from automation to true autonomy, we must reframe how we think about technology’s role from engineering to the factory floor. Here’s what it will take:

1. Establishing a basis of trust

The first barrier to effective industrial AI isn’t technological—it’s cultural. Engineers and operators have to trust that AI won’t compromise quality, introduce new failure points or minimize critical roles. In high-stakes industries like defense, a misstep isn’t just costly. It can be dangerous.

Trust is earned: AI should begin by augmenting skilled, high-judgment tasks, such as engineering review of design to specification, flagging deviations during inspection to prevent downstream manufacturing impact or offering predictive insights into machine utilization to optimize uptime. These kinds of copiloting systems keep humans in the loop while augmenting their capabilities to amplify their impact.

2. Augmenting skilled tasks, not replacing them

In the face of growing labor shortages, especially among experienced machinists and inspectors, AI offers a critical opportunity: not to replace people, but to make demanding roles more accessible. With nearly 60% of manufacturers citing workforce challenges as a top concern, the ability to support and scale skilled labor is essential.

For instance, Level 2 and 3 inspectors are increasingly difficult to find and retain. AI-enabled tools using computer vision and machine learning can highlight potential defects and support precision measurement verification, making it possible for newer technicians to contribute meaningfully under digital mentorship. This doesn’t just ease bottlenecks; it helps preserve and transfer institutional knowledge before it’s lost.

3. Targeting pain points before system-wide intelligence

While the vision of smart factories is compelling, without focused, practical steps, grand plans often struggle to deliver real impact. Rather than attempt top-down reinvention, manufacturers should start by solving specific, high-impact problems. In casting, additive and other complex processes, deformation and defects are notoriously hard to predict and correct. Manual workarounds are common, but they can be inconsistent and error-prone.

AI tools that automate tool path corrections or detect quality drift aren’t flashy, but they target exactly where manufacturers hurt the most. By focusing first on operational friction points, companies build a foundation for trust, adoption and measurable ROI, clearing the runway for broader system intelligence.

4. Planning for a holistic factory brain

Once trust and early wins are established, the next phase is integration. This is where the idea of a “factory brain” becomes real. An Intelligent Manufacturing Ecosystem would be an interconnected intelligence layer that links machines, people, and data to drive smarter decisions in real time.

Think of it as a digital nervous system, one that learns continuously from production patterns then dynamically predicts bottlenecks and reallocates resources. Just as pilots rely on avionics to manage complex systems, tomorrow’s factory leaders will rely on AI dashboards, simulations and real-time insights to oversee adaptive production environments. Human judgment won’t simply be replaced. It will be elevated. The goal of the most valuable AI in manufacturing is to augment human expertise, turning intuitive decisions into data-driven, highly accurate outcomes.

5. Amplifying human capability through digital mentorship

The risk of losing hard-won industrial knowledge is growing. As experienced workers retire, their expertise often leaves with them. Technical training pipelines haven’t kept up, and fewer young people are entering skilled trades.

AI can help bridge this divide. By learning from expert behaviors—how they think and troubleshoot, adapt inspection routines or respond to anomalies—AI systems can mentor less experienced workers, offering real-time guidance and contextual support. This “digital coaching” approach doesn’t just improve performance; it accelerates workforce development and keeps craftsmanship alive in a new form.

6. Building the future of factory AI

The future of industrial AI isn’t one of machine dominance. Our relationship with artificial intelligence must be a partnership. When designed thoughtfully, AI enhances human ingenuity, strengthens operations and enables companies to scale with confidence. It’s not about more automation; it’s about better autonomy, that remains agile, transparent and human-centered.

We don’t need sweeping digital promises. We need precise, human-first solutions that bridge the gap between theory and practice. And in doing so, we won’t just build smarter factories, we’ll build stronger, more resilient ones – and effective manufacturing for workers, owners, investors and end-users.

About The Author

Ivan Madera, CEO of Adaptiv, is a highly accomplished entrepreneur and visionary in the aerospace additive manufacturing industry, with over 25 years of innovation in executive management consulting and advanced manufacturing strategy and implementation.

Adaptiv is building toward the future of industrial AI by embedding intelligence into the heart of manufacturing and the eco-systems that support them. Adaptiv’s platform helps factories think, adapt and thrive, transforming siloed operations into cohesive, responsive systems. But technology is just the enabler. The real transformation starts by partnering with leading companies looking to gain a competitive edge and rethink the factories of tomorrow.

Did you enjoy this great article?

Check out our free e-newsletters to read more great articles..

Subscribe